Wyk CNC Lathe Grooving Turning Bar Cutter Boring Tool Solid Carbide Tool Mgr for Back Boring

Overview Our Advantages 1. A large number of standard stocks, the spot is fast. 2. Provide 24-hour pre-sales and after-s

Send your inquiryDESCRIPTION

Basic Info

| Coating | Altin, Tiain/Ticn/Tin/Altisin Nanocoating |

| Handle Type | Tungsten Steel Straight Shank |

| Structure | Integral |

| Blade Number | Single-Blade |

| Material | Carbide, Tungsten Steel, Tungsten Carbide |

| Type | Carbide Boring Tools |

| Precision | High Precision |

| Controlling Mode | CNC |

| Processing Type | Metal |

| Usage | General/High Speed |

| HRC | 45/55/58/62/65 |

| Tolerance | 0~-1 Wire |

| MOQ | 10PCS |

| Custom Support | ODM/OEM |

| Total Length | 40-75mm |

| Flute | 1 Flute |

| Apply to | Steel, Stainless Steel, Cast Iron |

| Transportation | Sea/Express/Air |

| Transport Package | 1 Plastic Tube, Set of 10 |

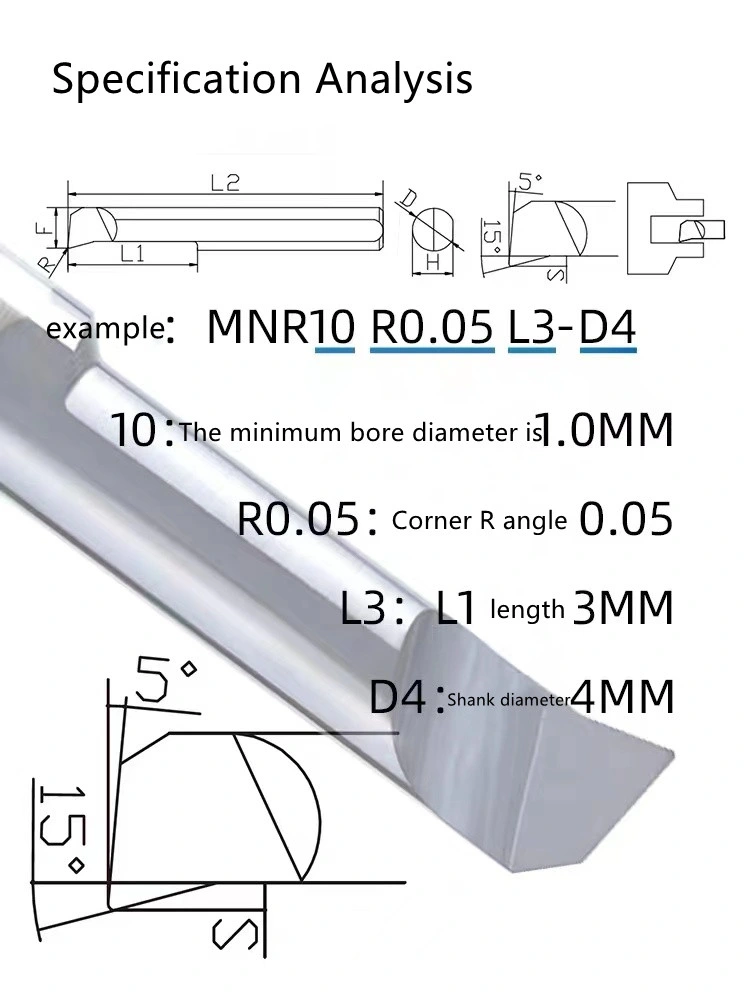

| Specification | MTR/MNR/MPR 4-8mm |

| Trademark | WYK |

| Origin | China, Jiangsu |

| HS Code | 8207609000 |

| Production Capacity | 20000/Month |

Product Description

Our Advantages

1. A large number of standard stocks, the spot is fast.2. Provide 24-hour pre-sales and after-sales service, reply within 3 minutes.

3. Ask customer service for free samples.

4.Undertake OEM customization/ODM for customers.

5. Large-scale dealer factories accept 80% of the prepaid payment from customers for delivery

6. Compensation for broken knife package.

Product Description

| 1. Product Name: Carbide Boring Tools | |||

| 2. custom size: 4mm,6mm,8mm,10mm,12mm | |||

| 3. Advantages: High Precision,Good Surface & Performace | |||

| Material: | YG10X /MH10FS&UH8(China)/K44 & K40 (German)/K44UF&K88UF(Cobalt collar) | ||

| Material: | Tungsten Carbide,Solid Carbide,Cemented Carbide | ||

| HRC: | 45/55/58/60/65 | ||

| Product Type: | Carbide Boring Tools | ||

| Coating: | Altin, Tialn, Tisin, Tin, DLC,Nano, Diamond | ||

| Helix Angle: | 10degree,15degree,25degree,35degree,45degree,55degree | ||

| Size: | Standard size or as your request | ||

| machine: | Imported Australian Anka machines and German Walther precision manufacturing | ||

| Suitable For: | Steel, Stainless Steel, Die Steel, Mould Steel, Carbon Steel, Cast Iron, Copper, etc. | ||

Praise Display

Product Features

1. Adopt new type of super fine grain tungsten steel base material with high wear resistance.2. Carbide bore boring tool with minimum boring 1.0 hole, universal for stainless steel/steel parts.3. Universal chamfering round shank, easy to use, good compatibility, clamping tighter without slipping.4. Support OEM, provide ODM, welcome friends from all walks of life to contact, win-win development.

Product Instructions

1. Before using the tool, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

2. The shorter the tool extends from the chuck, the better. If the tool extends longer, the speed, feed speed or cutting amount shall be reduced.

3. In case of abnormal vibration or sound during cutting, please reduce the rotation speed and cutting amount until the condition is improved.

4. Spray type and air jet type are preferred for steel cooling, which can improve the use effect of milling cutter.

5. Note: it is not applicable to low-speed machines such as bench drill and hand electric drill

Company Profile

The company is the production of integral carbide tools and other products research and development, production, sales in one of the enterprises, the main products are integral carbide tool series, carbide welding tool series, carbide indexable tool series, carbide CNC blade series, all kinds of non-standard tools. The company always adheres to the market orientation, close to customer needs, and continues to introduce suitable for communication electronics industry, mold manufacturing industry, automobile industry, rail transit, aerospace, medical equipment and other mechanical processing fields, and has a good reputation in the mechanical processing industry. The company's core purpose: "quality, innovation, integrity, speed. " The company has sufficient inventory, superior quality, according to the different needs of customers to map to sample non-standard custom tools, sincerely welcome friends from all walks of life contact and cooperation, adhere to the cutting tool field innovation, forge ahead, to provide customers with quality products and services.

Packaging & Shipping

| Packaging & Delivery | |||

| Selling Units: | Single item | ||

| Single package size: | 8.6X1.3X1.3 cm | ||

| Single gross weight: | 0.1kg | ||

| Package Type: | 1.One plastic pipe pack one piece,10 pcs per group2.Put goods enclosed with air bubble paper into box3.Other package is accepted according to customer's requirement | ||

| Package Type: | |||

| Lead Time: | ||

| Quantity(Pieces) | 1 - 100 | >100 |

| Est. Time(days) | 7 | To be negotiated |

FAQ

1. Are you a manufacturer? Do you have a factory?

We are professional manufacturer with more than 10 years experience in this field.

2. Can the price be reduced for large quantities?

Yes, bigger quantity orders are cheaper.

3. Do you inspect the finished product?

Yes, every production step and finished product will be inspected by QC department before shipment.

4. What is the lead time for mass production?

Honestly, it depends on the order quantity and the season you place your order.

5. Is free shipping available?

If you buy a lot of products, the shipping fee is negotiated with the factory.

6. Can you send the product to our forwarder in China?

Yes, if you have a forwarder in China, we are happy to send the product to them.

7. Can you produce special carbide tools?

Of course, we can. The main market for our factory has changed from standard end mills to special tools since 2015. We will use special tools to produce according to your drawings and samples.

Related Products

-

![Top Quality Precision Lathe Bt- Sk Milling Machine Tool Accessories Drill Chuck Tool Holder]()

Top Quality Precision Lathe Bt- Sk Milling Machine Tool Accessories Drill Chuck Tool Holder

-

![High Quality DIN2080 Nt Tool Holders Nt30 Nt40 Nt50 Collet Chuck Nt-Er Nt-Sln Nt-Fmb Nt-Apu Toolholders Nt30-Er32 Nt40-Sln8 Nt50-Fmb22 Collet Holders for CNC]()

High Quality DIN2080 Nt Tool Holders Nt30 Nt40 Nt50 Collet Chuck Nt-Er Nt-Sln Nt-Fmb Nt-Apu Toolholders Nt30-Er32 Nt40-Sln8 Nt50-Fmb22 Collet Holders for CNC

-

![Boring Bar Cutting Tool Holders for Lathe Machine]()

Boring Bar Cutting Tool Holders for Lathe Machine

-

![High Precision Boring Milling Face Head, F1]()

High Precision Boring Milling Face Head, F1